Keeping the air clean is a vital part of the operations within an industrial workspace and when dealing with floating dust particles, dust collectors are a crucial part of this process. The wrong type of dust collector will not only compromise the efficiency of dust extraction but the maintenance and operating costs as well. With this in mind, there are various factors to be considered to ensure that the right type of dust extraction system is chosen.

- Type of Dust: Knowing this can help avoid blockages and the need for frequent cleaning.

- Fine dust, generated from processes like polishing or sanding, would generally require a high-efficiency filter like cartridge filters.

- Coarse dust, from cutting or grinding processes, will require more heavy duty filters like bag filters, capable of capturing the larger dust particles.

- Moist or sticky dust can cause problems like clogging of the filters and may require filters that are custom designed and make use of specialized material.

- Volume of Air and Suction Power Required to Capture the Dust Particles:

- The volume of air flow required is measured in CFM (Cubic Feet per Minute) or CMH (Cubic Metres per Hour).

- The required air flow volume will vary depending on the size of the work area as well as the distance of the suction hood from the dust generation point.

- The required suction force is determined based on the capture velocity or velocity of air flow required to move the dust particles.

- In case of fine dust it can be between 100 – 150 FPM (Feet per Minute).

- In case of larger dust particles the velocity would need to be higher and is approximately 200 – 250 FPM.

- Volume of Generated Dust: Higher volumes mean more frequent cleaning.

- In case the volume of dust being generated is low or moderate, a regular dust collection system would suffice.

- However, in case there is a very large volume of dust being generated, the cleaning of the filters will need to be much more frequent which may hinder operation times.

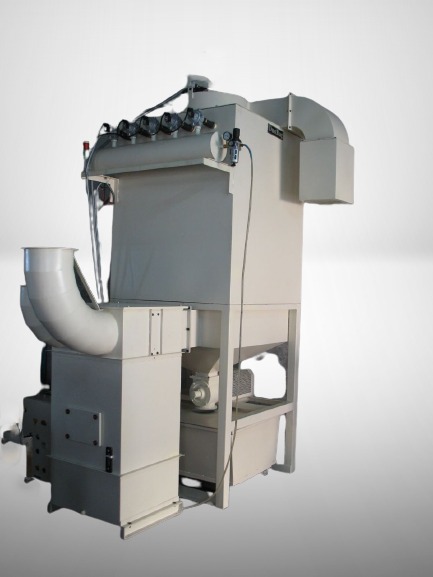

- For such cases, it is recommended to use a self-cleaning dust collector. The DustBag® Reverse-Pulsed Jet (RPJ) is a good example of this type of dust collector.

- Maintenance and Cleaning: Choose a dust collector that is easy to maintain.

- The collected dust needs to be disposed of and filters cleaned regularly to maintain operational efficiency of the dust collector.

- As mentioned earlier, pulsed jet dust collectors are examples of self cleaning dust collectors that can automate the filter cleaning process and reduce downtime.

- Safety and Compliance: Maintain all regulatory standards.

- Dust can be hazardous, especially in industries like food or metalworking.

- Some dust types are also flammable and even explosive. An example of this would be magnesium dust.

- Ensure that the dust collection system meets standards as per the pollution control laws. Additionally, check for additional safety standards like ATEX if there is a risk of explosion.

- Noise and Running Costs: Specific requirements for your dust collector.

- If noise is a concern in the shopfloor, ask about models with acoustic conditioning for quieter operation.

- Running costs include factors like energy use, maintenance schedule and filter life and replacement costs.

- All of the above factors should be considered carefully to avoid long term issues.

Overall, it is important to know what are the factors to be considered when choosing your dust collector.The right system will keep the air clean inside the shopfloor, protect employee health and keep running costs low, all of which are highly beneficial for an industry in the long term. For more expert advice on dust collectors, get in touch with us today.