Introduction:

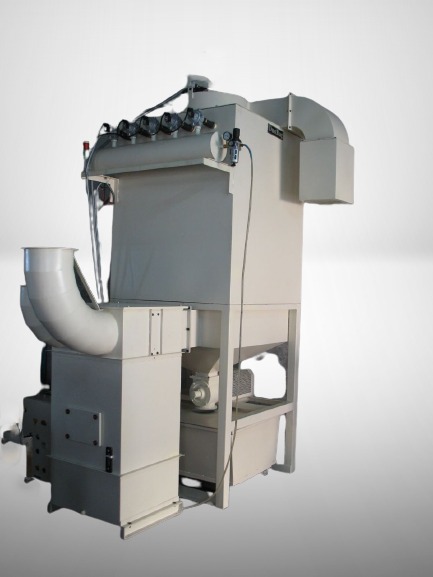

Here is a look into the successful implementation of the FumeKiller® model FK3600EM as a semi-centralized soldering fume extractor. The project demonstrates the capabilities of the FumeKiller® as an advanced soldering fume extraction system.

The Challenge: Control of Fumes generated from multiple Soldering Workstations

The client, an established electronics manufacturer, was making use of 9 soldering stations for a specific operation. This led to the release of a significant volume of soldering fumes in the work area, posing serious health concerns to the employees and violating air quality standards. There was also the additional point to be addressed that not all the work stations were in operation at the same time. The solution had to be custom designed to solve the issues at hand.

The Solution: Semi-Centralized Soldering Fume Extraction System using FumeKiller® model FK3600EM.

After a detailed site study, it was decided to use 3 units of the FumeKiller® model FK3600EM, with each unit being used for a set of 3 workstations, to provide a semi-centralized soldering fume extraction system to tackle the issue.

- Customized System Design: Due to space constraints within the work area, which disallowed the use of a complete centralized system or individual soldering fume extractors for each workstation. The use of 3 separate FumeKiller® units to facilitate a semi-centralized design solved this issue.

- Powerful Extraction Technology: The FumeKiller® system boasts cutting-edge electrostatic filtration technology, which enables it to function as an effective and efficient soldering fume extractor. This feature dramatically decreases the release of pollutants into the ambient air, improving workplace safety and air quality.

- Semi-Centralized Control: The semi-centralized arrangement provides an additional benefit. In case of a breakdown of any one of the units, the remaining units continue to operate so that there is at least partial fume control and no significant deterioration of air quality.

Results and Impact: Implementation of the FumeKiller® as a soldering fume extractor provided excellent results including:

- Improved Air Quality: Harmful soldering vapours were properly caught and filtered, resulting in a safer and healthier working environment for its staff.

- Regulatory Compliance: Our solution enabled the customer to comply with stringent air quality rules, avoiding potential legal issues.

- Improvement in Production Efficiency: The improved air quality played a direct role in improving production efficiency.

Conclusion:

The success of the project clearly demonstrates the efficacy and efficiency of the solution designed by Powertech Pollution Controls. By addressing the client’s soldering fume issues with a semi-centralized fume extraction system, noticeable improvements were observed in air quality, worker safety and subsequently environmental responsibility. In case of any requirements for fume control or any other type of air pollution control systems, get in touch with us today.