Introduction: Extraction of Oil Mist from CNC Machining Process

The FumeKiller® finds use across a variety of applications. Primarily used as a welding fume extractor or soldering fume extractor, the FumeKiller® also finds use as an effective oil mist collector. Following are the details of a successful application of the FumeKiller® for the extraction of oil mist generated from a CNC machining process.

The Challenge: Issues due to Oil Mist in the Shop Floor

Nexteer, a well known and established player in the manufacturing industry was facing an issue commonly faced during the CNC machining process – oil mist.

The process involved the use of neat cutting oil during the machining process which led to the generation of oil mist. The mist would escape into the shopfloor which led to various issues, including:

- Reduction in air quality within the shopfloor.

- Mist settling within the gaps on the machine which may lead to breakdowns and system failures.

- Loss of oil mist means loss of usable neat cutting oil over time.

Any solution provided to the customer would need to be designed with all the above problems in mind and effectively solve each issue.

The Solution: FumeKiller® model FK2000EM

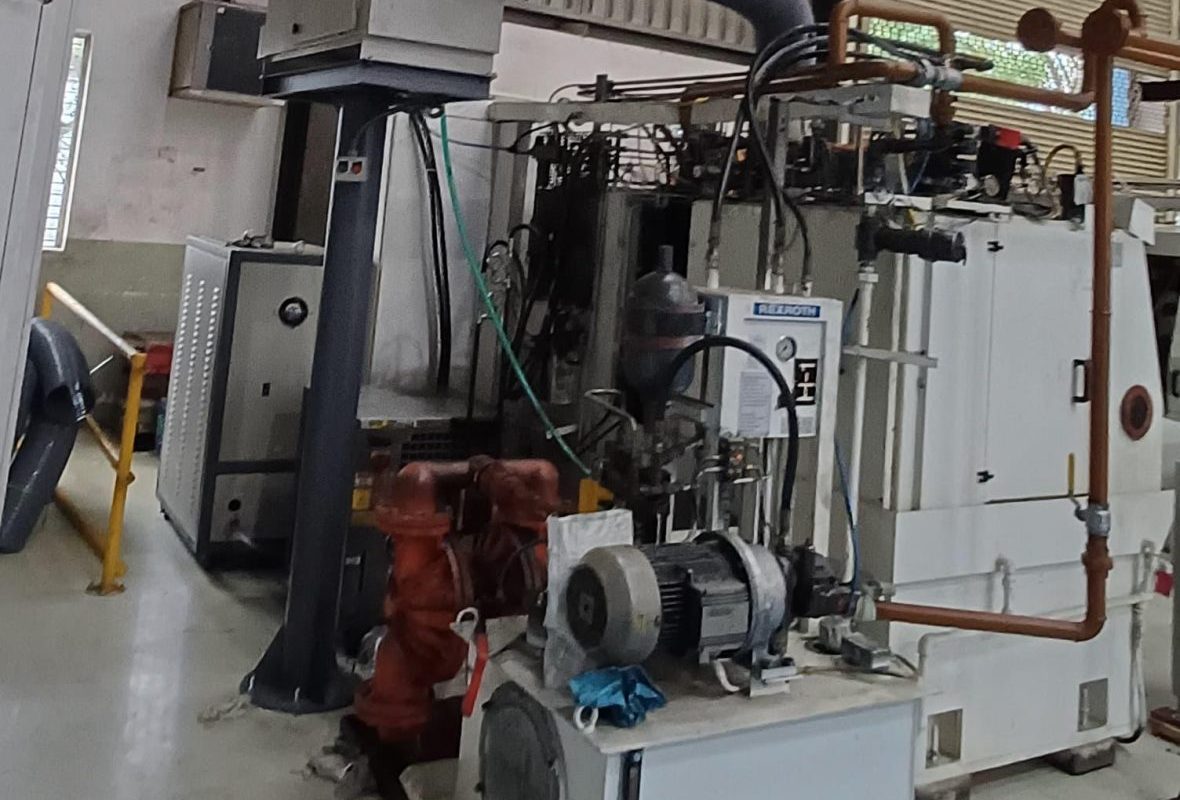

To address both the primary and secondary issues, a careful study of the work area was done before suggesting a FumeKiller® model FK2000EM for the capture and control of the generated oil mist. The unit was to be mounted on a 6.5 ft. pipe stand positioned close to the CNC machine. This positioning would also provide an additional advantage of being able to collect the filtered oil mist from a drain point provided on the FumeKiller® unit.

The logic used for this solution is primarily based on the concept of mist evacuation where the entire volume of air within the CNC machine is evacuated within a certain time, usually 5-10 seconds. This ensures that when the doors of the machine are opened there are no mist particles that escape into the shopfloor.

Results and Impact: Successful Implementation of FumeKiller®

The implementation of the FumeKiller® was a success which allowed for multiple benefits to our client:

- Improvement in Air Quality: The complete volume of air within the CNC machines, which would include the generated oil mist, was being evacuated before the doors were opened and therefore, with no release of oil mist into the shopfloor, it resulted in a significant improvement in the air quality.

- Operational Efficiency: The FumeKiller® model FK2000DPEM is a single oil mist collector unit that was equipped with a dual-pass filtration system, allowing for greater efficiency of filtration and therefore, even cleaner air being released into the shopfloor.

- Cost Savings: Because the filtered oil could be collected and reused, the neat cutting oil for the process was more efficiently and economically used, which resulted in a direct reduction in operational costs.

- Regulatory Compliance: The successful implementation of the FumeKiller® as an oil mist collector resulted in the customer meeting the required air quality standards within the shopfloor.

Conclusion: The Capability of FumeKiller®

The successful execution of the project serves as another example of the capability and versatility of the FumeKiller® as a fume extractor as well as an oil mist collector. It can be stated with confidence that the FumeKiller® is probably one of the most effective air pollution control systems currently available. For more details about the FumeKiller®, visit our website or you can get in touch with us for any requirement you may have for air pollution control solutions.